MTBF refers to the probability of a failure occurring in a piece of equipment. It is primarily useful with repairable equipment or swappable components. MTBF is used to

estimate the statistical need for repair services.

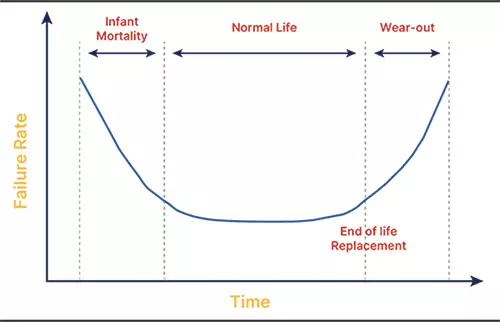

You can calculate MTBF directly by counting failures and dividing the number of failures into the total operating time. However, MTBF is typically estimated by a statistical analysis of the components used in the product and their individual track records. MTBF is expressed in hours. For example, an MTBF of 100,000 hours indicates that, on average, you can expect a failure every 100,000 hours of equipment service. MTBF calculations assume a constant rate of failure during a product’s service life. However, actual failures are more common early in the product’s life and late, near the end of the product’s life.

MTBF is a more useful metric for large installations than for individual products. For example, an average personal computer (PC) power supply has an MTBF of 100,000 or more hours (11 or more years). It is rare for a PC to operate without being declared obsolete long before 11 years have passed. Therefore, a user does not need to plan for a power failure during his or her PC’s lifetime.

However, the example of a data center, with thousands of servers, tells a different story. Statistical averaging, along with MTBF, would show that some of those power supplies will fail before their useful life is up. The quantity of spare replacement supplies on hand will be based on the overall MTBF for the power supplies in the installation.