Psi vs Theta

Feb 5, 2019

This whitepaper describes how the maximum operating temperature of a converter can be determined and explains the difference between thermal impedance (Theta) and the thermal characterisation figure (Psi).

Introduction

A question often asked of RECOM technical support is, “What is the maximum operating temperature?” for a particular converter. Although there are several ways to determine this, it is still not an easy question to answer precisely. This is not because we don’t know how to characterise our products, but because the final answer depends on many different factors, many of which have nothing to do with the converter itself.

All operating power converters generate heat (caused by the internal power dissipation), which needs to escape the package to the ambient surroundings if the converter should not be overheating. Typical “hot spot” sources of heat are the power semiconductors such as transistors and diodes, which have switching junction losses, inductive components such as transformers and inductors that have both DC and AC losses and power resistors used in snubbers and filters with I²R losses. The design engineer has to minimise these losses to maximise the efficiency of the converter, but they are unavoidable.

How the internal heat escapes from a hot junction inside a semiconductor package is also dependent on many factors. The shortest ‘path-of-least-resistance’ is typically from the junction to the top surface of the case or housing, but from there, the heat energy can escape to the surroundings by either convection, conduction or radiation. Furthermore, there could also be thermal conduction paths to the surroundings via a baseplate using heatsinks or gap-pads to the housing, through the mounting pins to the PCB itself or the sides or bottom surfaces of the converter case.

Depending on the setup, even the results from thermal measurements may differ significantly. For example, what is ‘free air convection’ cooling? Is the cooling flow of air completed unrestricted? Or could there be a local build-up of heat caused by closely positioned components, adjacent boards blocking the airflow or poorly ventilated cases? Additionally, are the thermal measurements done with ‘still air’ with zero LFM or with free-air movement (20 LFM) or with forced-air cooling (100 LFM)?

For board-mount converters, there may be other issues such as whether the board is mounted horizontally or vertically if the board is made from glass fibre (FR4) or uses a different substrate or what copper thickness is used for the tracks. All of these factors can affect the thermal performance of the parts mounted on the board.

All operating power converters generate heat (caused by the internal power dissipation), which needs to escape the package to the ambient surroundings if the converter should not be overheating. Typical “hot spot” sources of heat are the power semiconductors such as transistors and diodes, which have switching junction losses, inductive components such as transformers and inductors that have both DC and AC losses and power resistors used in snubbers and filters with I²R losses. The design engineer has to minimise these losses to maximise the efficiency of the converter, but they are unavoidable.

How the internal heat escapes from a hot junction inside a semiconductor package is also dependent on many factors. The shortest ‘path-of-least-resistance’ is typically from the junction to the top surface of the case or housing, but from there, the heat energy can escape to the surroundings by either convection, conduction or radiation. Furthermore, there could also be thermal conduction paths to the surroundings via a baseplate using heatsinks or gap-pads to the housing, through the mounting pins to the PCB itself or the sides or bottom surfaces of the converter case.

Depending on the setup, even the results from thermal measurements may differ significantly. For example, what is ‘free air convection’ cooling? Is the cooling flow of air completed unrestricted? Or could there be a local build-up of heat caused by closely positioned components, adjacent boards blocking the airflow or poorly ventilated cases? Additionally, are the thermal measurements done with ‘still air’ with zero LFM or with free-air movement (20 LFM) or with forced-air cooling (100 LFM)?

For board-mount converters, there may be other issues such as whether the board is mounted horizontally or vertically if the board is made from glass fibre (FR4) or uses a different substrate or what copper thickness is used for the tracks. All of these factors can affect the thermal performance of the parts mounted on the board.

Thermal Impedance, Ɵ

The classic way to calculate the maximum operating temperature is to use the thermal impedance figure (Theta or the symbol Ɵ). This essentially defines the path-of-least-resistance route, which the heat generates from a hot spot; for example, the junction of a switching transistor, travels out through the converter via thermal conduction and then convects away from the top surface to the ambient surroundings.

Diagrammatically, it can be shown as a series of thermal impedances: ƟJP between the junction and the transistor packaging; ƟPM packaging and the moulding material; ƟMC the moulding material and the plastic or metal case and finally ƟCA the case and ambient.

Diagrammatically, it can be shown as a series of thermal impedances: ƟJP between the junction and the transistor packaging; ƟPM packaging and the moulding material; ƟMC the moulding material and the plastic or metal case and finally ƟCA the case and ambient.

Fig. 1: Theta junction-ambient thermal impedance model

Theoretically, it would be possible to find out or estimate all these different Theta values by studying the specifications of all of the different materials used in the part; but in practice, it is simpler to use the overall thermal impedance figure given in the manufacturer’s datasheet to calculate the maximum operating ambient temperature.

Step 1: calculate the internal power dissipation, Pdiss:

Where ƞ is the efficiency of the converter (use the figure given in the datasheet or, better still, use the efficiency/load graph to find out the operating efficiency at the load being used)

Step 2: calculate the case over-temperature, Tover

Where Rth is the overall thermal impedance figure given in the datasheet (in Kelvin per Watt)

Step 3: calculate the maximum operating ambient temperature:

Where Tcase,max is the maximum case (or baseplate) temperature given in the datasheet.

For example, from the RBBA3000-50 datasheet: Take the RBBA3000-50 with 48V input voltage, 24V output voltage, 50A output current:

What is the maximum ambient operating temperature?

Step 1: calculate the internal power dissipation, Pdiss:

Where ƞ is the efficiency of the converter (use the figure given in the datasheet or, better still, use the efficiency/load graph to find out the operating efficiency at the load being used)

Step 2: calculate the case over-temperature, Tover

Where Rth is the overall thermal impedance figure given in the datasheet (in Kelvin per Watt)

Step 3: calculate the maximum operating ambient temperature:

Where Tcase,max is the maximum case (or baseplate) temperature given in the datasheet.

For example, from the RBBA3000-50 datasheet: Take the RBBA3000-50 with 48V input voltage, 24V output voltage, 50A output current:

What is the maximum ambient operating temperature?

Thermal Characterisation figure, ψ

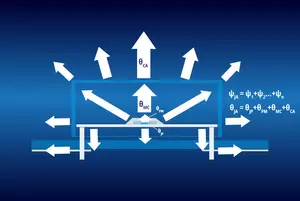

The thermal characterisation figure (Psi or the symbol ψ) recognises that the path-of-least-resistance thermal impedance is not truly representative of the actual performance of many components. This is because there are usually multiple paths in which heat can be extracted from a hot spot – not least through the pins – in some converter designs, up to 30% of the internal heat can be extracted through the pins and thereafter dissipated via the PCB tracks and copper planes to ambient.

As such, converters that use 3DPP® construction are designed so that the majority of the heat will be conducted away via the copper pads on the underside of the converter.

As such, converters that use 3DPP® construction are designed so that the majority of the heat will be conducted away via the copper pads on the underside of the converter.

Fig. 2: Psi Thermal characterisation multiple thermal path model

In general, ψJA is lower than ƟJA, but depending on ...

| Series | |||||||

|---|---|---|---|---|---|---|---|

| 1 |

|

RBBA3000

Focus

|

|

|