Planar versus Toroidal Transformers: What is the difference?

The transformer is at the core of any DC/DC converter design and is the most critical component in determining the overall performance.

Traditionally, transformers and inductors are wound components. Most mass-produced low-power DC/DC converters use hand-wound toroidal transformers; it is extremely difficult to develop an automatic manufacturing process for a transformer that requires up to six separate windings with a diameter core as small as 6mm with a 3mm hole. Manufacturers such as RECOM have developed automatic winding machines to manufacture such tiny toroidal transformers, but such solutions are very hard to find.

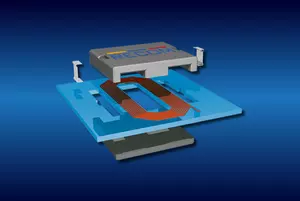

Planar magnetics have existed since the 1980s, but the manufacturing process was initially prohibitively expensive, so planar transformers had limited market penetration outside of specialized applications. However, as manufacturing technology has advanced, the cost of planar transformers has decreased, allowing for the development of new applications.

Traditionally, transformers and inductors are wound components. Most mass-produced low-power DC/DC converters use hand-wound toroidal transformers; it is extremely difficult to develop an automatic manufacturing process for a transformer that requires up to six separate windings with a diameter core as small as 6mm with a 3mm hole. Manufacturers such as RECOM have developed automatic winding machines to manufacture such tiny toroidal transformers, but such solutions are very hard to find.

Planar magnetics have existed since the 1980s, but the manufacturing process was initially prohibitively expensive, so planar transformers had limited market penetration outside of specialized applications. However, as manufacturing technology has advanced, the cost of planar transformers has decreased, allowing for the development of new applications.